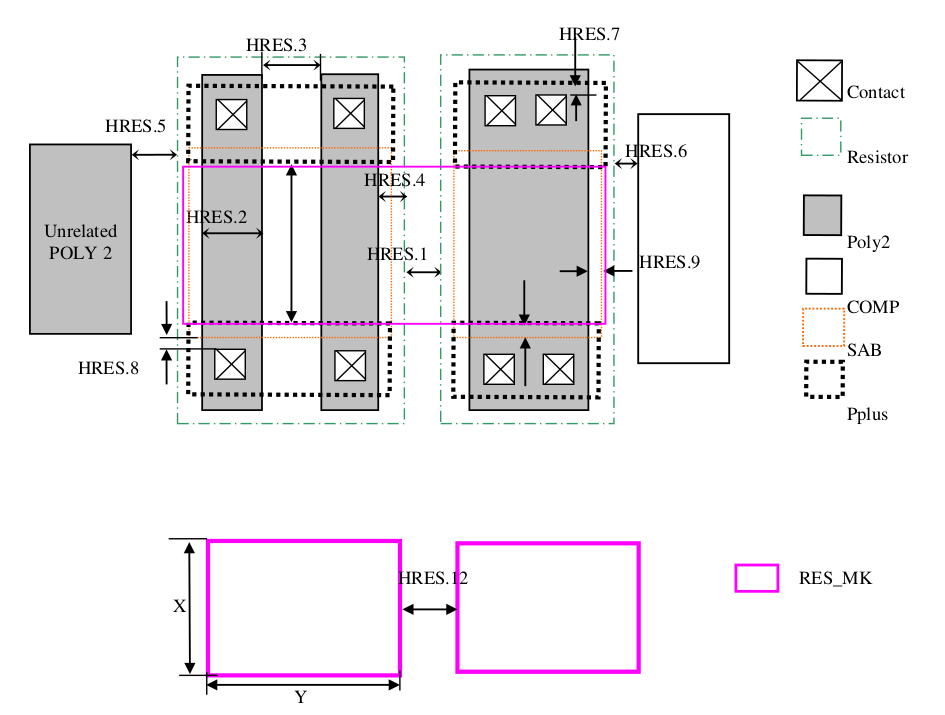

10.3 HRES Poly Resistor (PHRES) (Optional with one additional mask)¶

This section defines the rules for Un-salicide P-type high sheet resistance poly resistor. This uses one additional mask (L63) to have special implant on high Rs poly resistors. Here resistor width is determined by Poly2 width and the resistor length is determined by Pplus to Pplus space on Poly2. In order to realize this resistor “Resistor” layer must be drawn covering the Poly2.

RULE NO. |

DESCRIPTION |

Rule |

HRES.1 |

Minimum space Note : Merge if the spacing is less than 0.40 um |

0.4 |

HRES.2 |

Minimum width of Poly2 resistor |

1 |

HRES.3 |

Minimum space between Poly2 resistors |

0.4 |

HRES.4 |

Minimum RESISTOR overlap of Poly2 resistor |

0.4 |

HRES.5 |

Minimum RESISTOR space to unrelated Poly2 |

0.3 |

HRES.6 |

Minimum RESISTOR space to COMP |

0.3 |

HRES.7 |

Minimum Pplus overlap of contact on Poly2 resistor |

0.2 |

HRES.8 |

Space from salicide block to contact on Poly2 resistor |

0.22 |

HRES.9 |

Minimum salicide block overlap of Poly2 resistor in width direction |

0.28 |

HRES.10 |

Minimum & maximum Pplus overlap of SAB |

0.1 |

HRES.11* |

Maximum current density of Poly2 resistor (mA/um) |

1 |

HRES.12 |

P type Poly2 resistor (high sheet rho) shall be covered by RES_MK marking. RES_MK length shall be coincide with resistor length (Defined by Pplus space) and width covering the width of Poly2. If the size of single RES_MK mark layer is greater than 15000um2 and both side (X and Y) are greater than 80um. Then the minimum spacing to adjacent RES_MK layer |

20 |

Note